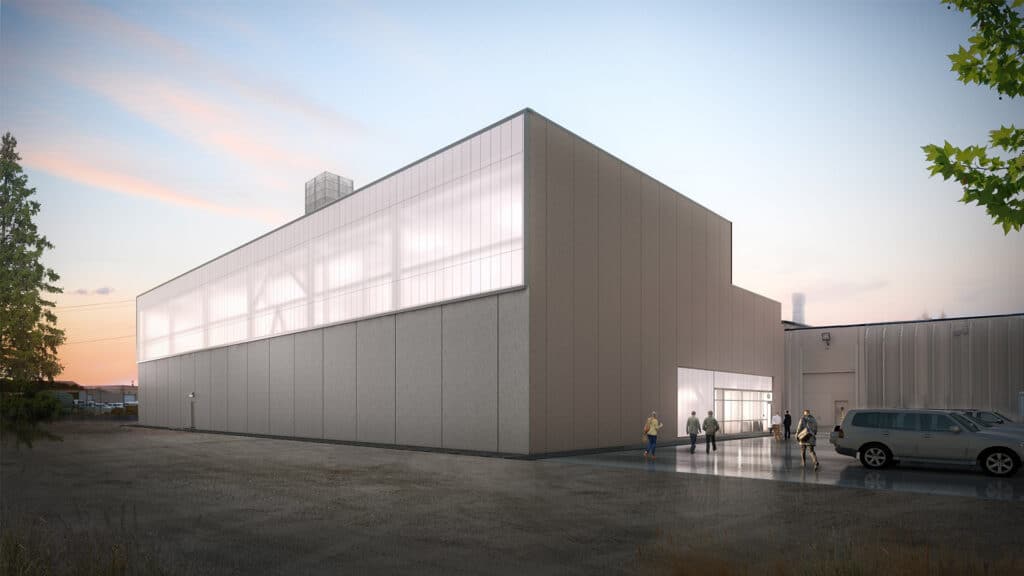

UND’s new, natural gas-powered steam plant is up and running before the start of the new school year.

The new plant, which is a partnership between UND and Johnson Controls, is the culmination of about a year of construction and includes up-to-date technology that is designed to make the plant easier to manage, according to Mark Johnson, director of operations at UND.

“We’ve moved a full century in our technology,” he said. “I never thought I’d see this. This is an unbelievable plan.”

The plant was fully operational on July 1, which was on schedule. Johnson said there had been test runs throughout the process.

Mike Pieper, associate vice president for facilities at UND, said there is some additional work to do on the distribution lines that will wrap up this summer. Demolition of the old plant should be done by the end of October.

The old plant, which had been a part of campus for more than 100 years, was powered by coal, natural gas and fuel oil as back up.

The plant was becoming inefficient and included different-sized boilers, some of which needed parts that were specially made for the university because the part no longer existed.

“Instead of using 75-year-old boilers, we’re using brand new ones, so it’s much more efficient and much more energy efficient,” Johnson said.

Pieper said because all of the boilers in the new facility are brand new and the same, the facility will be easier to manage.

After demolition of the old plant is complete, the university plans to turn the site into a parking lot in order to add more convenient parking options for students, faculty and staff.

Between the building and the distribution lines and other campus upgrades, the total cost for the project was about $90 million. The endeavor was a private-public partnership, or a P3, between the entities and did not require any state funds to complete.

Under the private-public partnership, Johnson Controls operates the steam plant for the university. Some of the staff that work at the new facility were also a part of the old plant.

The project also cuts down on a significant amount of deferred maintenance for the university.

Additionally, the program retrofits buildings across campus to reduce energy consumption — upgrading building automation, lighting, equipment and HVAC. Together, the program will save more than $1 million per year for UND.

The new plant will continue to have distribution lines to local organizations, including Altru, the Ralph Engelstad Arena, the School for the Blind and Lake Agassiz Elementary School.

Operating with primarily natural gas, the new facility will reduce the campus’ carbon dioxide emissions by about 40,000 metric tons a year and would also reduce landfill space taken up by ash produced by the current plant.

During the ceremonial groundbreaking for the plant in October 2018, then President Mark Kennedy said these reductions are the equivalent of taking 8,600 cars off the road and the carbon sequestration would equal about 74 square miles of forest, or the size of Grand Forks and Fargo combined.

“I contend that we’re the cleanest flagship university or cleanest land-grant university,” Pieper said.

Pieper said the private-public partnership has resulted in other P3s in the North Dakota University System, and has allowed the university to pursue other P3 solutions for UND.

The project was recently awarded the 2020 Sustainability Innovation Award for its public-private partnership. The award is from APPA, a professional association for facilities management professionals in education. The Sustainability Innovation Award is designed to recognize and promote unique and innovative sustainable practices in the educational facilities and campus environments.